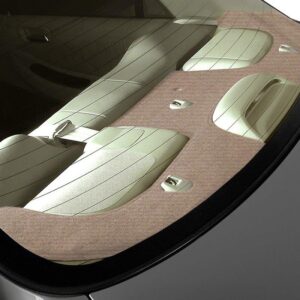

Coverking® – Satin Stretch™ Indoor Custom Car Cover

$231.29Superior Protection

Indoor car cover provides superior protection for your vehicle from dirt, dust, nicks, bumps and scratches.

Soft Synthetic Fabric

Made from form-fitting lycra fabric and a fleece lining for double protection.

Elasticized Edges

Elasticized edges keep dirt and dust out.

Custom Fit

Precise CAD design to ensure perfect fitment on specific make, model and year vehicle.

4-Year Warranty

Backed with 4-Year Warranty, the product will be replaced or repaired if it fails under normal use.

Made in the USA

Coverking builds the Satin Stretch™ custom car covers in the United States.

Materials. Taking into consideration the decades of experience, Coverking designs its own fabrics, because the car cover quality depends greatly on the properties of the fabric used. The world’s leading textile mills handle the custom fabric manufacturing for Coverking, based on the research of Coverking’s team of engineers, that specify the exact material composition and construction needed for each type of a car cover produced. All fabrics for outdoor car covers are breathable to avoid the “greenhouse” effect if any water will get under the cover. Coverking was the first to bring colored materials and two-tone designs, supplying the materials that withstand the effects of the sun and don’t fade.

Pattern Fit and Design. Coverking does not save on material types used, spending approximately 30 yards of fabric on average car cover they produce. Other companies often use “chopped up” patterns to save around 20% of materials to the prejudice of style, resulting in “patchwork” look. Not to mention the fact that extra patches equal extra leakage risks. Coverking is proud to deliver all-custom look and experience and will never treat these values for a couple yards of fabric to save.

Production Technology. High quality of Coverking Custom Car Covers starts with CAD/CAM systems performing precise design and cutting to ensure that the ready product has least seams possible for true custom look. All seams are sewn overlapped, with double needle and heavy, wax-coated thread to ensure durable, leak-resistant seams that will serve you the longest lifetime possible. Double seams ensure durability, in case if the main seam will fail. Indoor Custom Car Covers feature “blind seam” technology that is ideal for indoor, show-car conditions. Neoprene elastic tensioners are sewn in the front and rear of every Coverking Custom Car Cover. Optional security kit features protected grommets, sewn in the sides and covered to be invisible when cover is on the car.

The Coverking® company was founded in 1986 in Southern California by an Industrial and Electrical Engineer, that previously worked in Aerospace Defense industry. Utilizing the latest CAD/CAM systems borrowed from Aerospace industry, the company managed to shorten the manufacturing process from nearly a month to nearly a single day. Since its launch, the company made a huge leap and has purchased several automotive companies later, some of which dated back to 1974. The company started with Dash Covers products and extended its products line with Custom Floor Mats, Custom Car Covers, Custom Seat Covers and Custom Sunshields. Growing production volumes did not change the company’s main focus – creating high quality products that will serve their best to the customers and their vehicles.